行业新闻

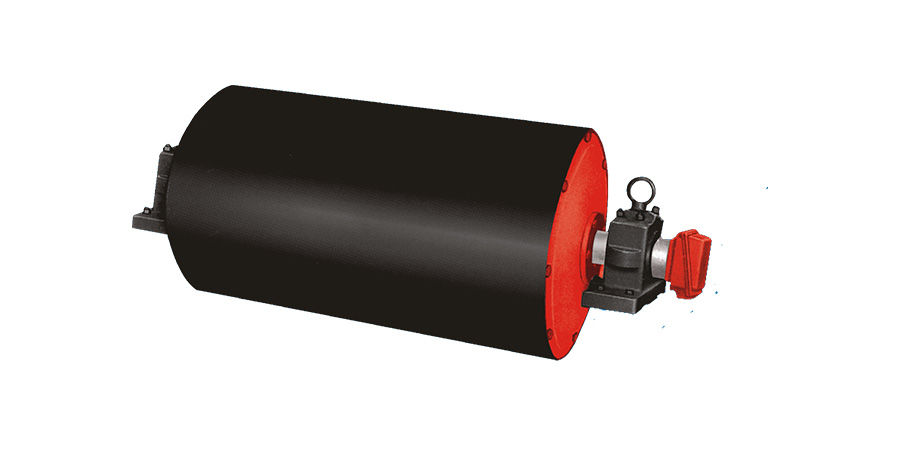

Industry News电动滚筒包胶处理方式详解。

电动滚筒包胶(橡胶包覆)处置的两种计划: 滚筒外表热硫化注胶和滚筒外表冷粘式包胶

1.滚筒外表热硫化包胶的特性:

A、必需把滚筒拆卸掉拉回热硫化厂家施工,拆卸滚筒时劳动强度大、时间长、费用高。

B、热硫化包胶胶料填料多,含胶量极低、耐磨性差,胶面极硬、因惹起物料粘附,所硫化胶片与滚筒外表会呈现整体零落及成块掉落现象,运用寿命极短。

2.滚筒外表冷粘式包胶的特性:

A、无须拆卸滚筒,能够现场施工,操作便当快捷,即粘即用;

B、橡胶板密实度高、耐磨性极强,胶板弹性佳、防粘附性能好,与滚筒外表粘贴结实、永不零落,运用寿命为热硫化包胶的数倍。

Electric drum package plastic (rubber coated) two kinds of treatment plan: drum looks hot vulcanization glue injection and the appearance of cold bonding type rubber covered roller

Characteristics of the 1 roller hot vulcanized rubber clad appearance:

A, necessary to remove back roller heat vulcanization factory construction, removing cylinder high labor intensity, long time and high cost.

B, heat curing bag rubber filler, resin content is extremely low, poor wear resistance, adhesive surface very hard, caused by the adhesion of the film material, and drum vulcanizing appearance will present the overall scattered and blocks the phenomenon, the use of short life.

Characteristics of encapsulated appearance 2 roller cold bonding type:

A, without the need of disassembling the drum, to site construction, operation convenient, is stuck with;

B, rubber plate with high intensity, wear resistance strong, rubber elastic good, anti adhesion performance, and the drum adhered to the surface of solid, never fall off, service life of hot vulcanization rubber covered several times.